3D printing a space rocket (Day 338)

30th April 2015

Regular readers of my blog will know that I have shared many chemical engineering good news stories about space: the final frontier.

From chemical engineers who also happen to be astronauts (see my blog 'A path to the stars') to chemical engineers developing technology to power a lunar space mission with poo, and even chemical engineers who have created a template for extra-terrestrial life. It's clear to see that chemical engineering is not limited to just planet Earth.

So you can imagine my delight when I happened across a piece of news that combined space exploration and 3D printing. Researchers at NASA's Glenn Research Center in Ohio, US, have successfully printed a space rocket engine part that can function at both extremely high and low temperatures.

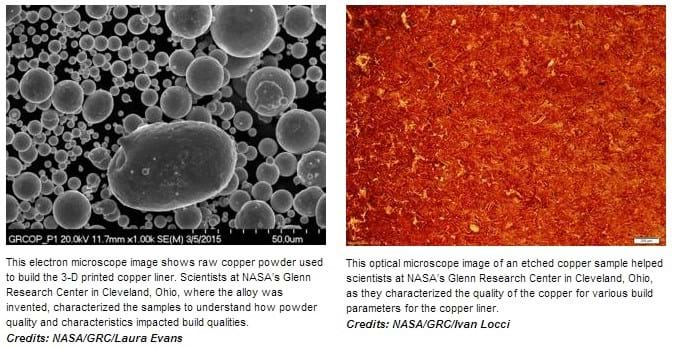

Copper is used in space rocket engines as it can withstand harsh conditions, such as extreme temperature changes. So the team at NASA created the copper combustion chamber liner using selective laser melting 3D printers.

Zach Jones, a materials engineer who lead the project at NASA, said: "Copper is extremely good at conducting heat.

"That’s why copper is an ideal material for lining an engine combustion chamber and for other parts as well, but this property makes the additive manufacturing of copper challenging because the laser has difficulty continuously melting the copper powder."

The combustion chamber was 3D printed using a copper alloy, GRCo-84, developed at the Glenn Research Center.

The process involved using 8,255 separate layers of copper powder, which was then compacted using heat to build up one layer at a time. All in all, the final product took ten days and 18 hours to print.

“Building the first full-scale, copper rocket part with additive manufacturing is a milestone for 3D printing,” explained Steve Jurczyk, associate administrator for the Space Technology Mission Directorate at NASA Headquarters.

He continued: “Additive manufacturing is one of many technologies we are embracing to help us continue our journey to Mars and even sustain explorers living on the Red Planet.”

This innovative technological breakthrough could also help additive manufacturing companies around the world make best use of their 3D printing processes. NASA will be releasing their data on the process via their Materials and Processing Information System (MAPTIS) to share their wealth of knowledge.

Being able to 3D print in copper is a giant leap forward for NASA and their space rocket engines. And who knows, perhaps one day, all space rockets will be printed - to 3D infinity, and beyond!

Do you work with 3D printed materials? If so, get in touch via the blog and share your work.